450 Rigby Project, Dreaming Big

By Keith Wood

Sometimes, the desire to own something can defy logic. This is the story of a special rifle, one built by hand to meet the dreams of a client. In today’s throwaway society, this rifle is a rare example of a complete commitment to quality. A rifle built to serve a purpose but built to be the best that it could be. L.B. is an experienced big game hunter with several quality rifles at his disposal. He certainly didn’t “need” another rifle. There’s little fun to be had in practicality, though. L.B. knew what he wanted and he knew who he wanted to build it.

“It started as a young kid, reading stories about Africa and professional hunters and dangerous game,” L.B. said. “I fell in love with classic Mauser's, open-sighted rifles and big cartridges. I always thought it would be kind of neat to have a professional hunter’s type gun of my own someday. But being lefty and young with limited resources, I didn’t think it would ever happen. Then, one day, after many years of hard work and good fortune I realized that I had the means to actually commission this type of rifle, so I got together with D’Arcy and talked him into building me one.”

L.B.’s rifle would be a heavy bore, built to face potentially dangerous game. A functional work of art with classic lines, this left-handed Mauser would be chambered in the mighty yet esoteric 450 Rigby. Most importantly, this rifle was built to function. It had to feed, fire, extract and eject as if L.B.s’ life depended on it. Because, one day, it might.

Let’s begin with the chambering. Though he’d initially intended the rifle to be chambered in .416 Rigby, L.B. ultimately decided on the London firm’s larger creation, the .450 because it fit his idea of a specialized, open sighted dangerous game rifle just a bit better. The .450 Rigby is a relatively new cartridge by big bore standards, developed in 1994 by John Rigby & Company. The .450 is, essentially, a .416 Rigby necked up to accept a .458 bullet. This cartridge bests the .458 Lott by 200 feet per second of muzzle velocity and does so without a belt. In short, a stopping rifle, ideal for Africa’s heaviest game.

One of L.B.’s stylistic inspirations for this project was the .416 Rigby carried by Professional Hunter Harry Selby. This iconic rifle wore only iron sights, which was the arrangement that L.B. wanted, but with a slight twist; L.B. wanted a ghost-ring rear sight instead of express leaf. Many experiences hunters/shooters are convinced an appropriately designed rear aperture is superior to an open sight in nearly all respects, so that route was chosen. “D’Arcy’s ghost-ring peeps are just so elegant and nicely done, it had to have one.”

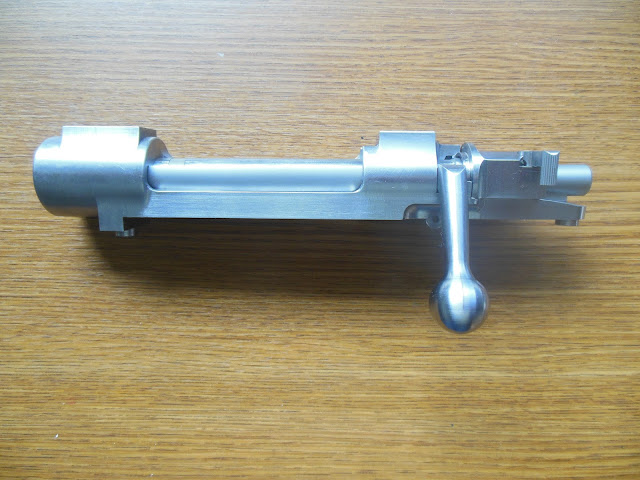

Like Selby, L.B. is left-handed. Unlike Selby, he wanted his to be a true left-handed rifle – thinking that, had one been available in his time, Selby might have used one himself. Even now, the number of makers making a left-handed Mauser M98 is a short one. After conferring with D’Arcy, L.B. settled on a German-made FZH. D’Arcy being D’Arcy, took things a bit further. “I had the chance to examine a right-hand FZH before I began the 450 project, and since this would likely be the last Left-Hand Magnum 98 that I will ever assemble I wanted to use the best Left-Handed receiver available”. “I called FZH and inquired whether I could get a receiver with a solid bottom like the older Mauser and FN target receivers.” A solid-bottomed receiver would allow D’Arcy to set up and machine the feeding geometry to his own specifications, taking the .450 Rigby’s dimensions specifically into account. “They [FZH] said no, which did not surprise me. I then called Ralf Martini as I knew he ordered these receivers in small lots and he got me exactly what I wanted. At Ralfs one odd request FZH had an idea the receiver would be going to me and didn't want the action being modified by an unqualified buffoon. Ralf assured them that I had more than one ball peen hammer and knew how to use them.”

The receiver arrived just as requested, in an annealed state and very nicely machined. German firearms engineering at its finest.

L.B. had several other stylistic and functional goals for the rifle, the most important of which was the design of the stock. “I really wanted it to handle like a shotgun,” he said. “I've done a fair amount of shotgun shooting, mainly trap and sporting clays. When you're shooting a shotgun, gun fit is so important because your dominant eye is essentially your rear sight. I wanted to take some of those [custom shotgun] ideas and put it into my heavy rifle and that's what we did.”

L.B. loved the classic lines of D’Arcy’s stocks but with a few important tweaks. He wanted a larger fore-end and also requested a palm swell added to the grip layout and a functional thumb flute on the left side of the comb. The stock blank selected was a piece of California French Walnut that was purchased from Scott Wineland at one of the SCI conventions. This blank was well laid out, dense and very attractive.

During the planning process, L.B. examined numerous classic express rifles and came away determined to borrow some of their design cues, paying homage to a proud gun making tradition. “I loved the way the front bridge of the old Rigby’s were scrolled with the logo on it,” he said. “I also liked all the lettering and badging that was on a lot of those original Mauser's and I wanted to replicate that on my gun. This is going to sound a little hokey but my vision was that this would be bit of a tribute gun for PHs all over the world. I also wanted to give credit to Mauser and what they've done and even Rigby. The old Rigby London guns were so classically and tastefully put together.”

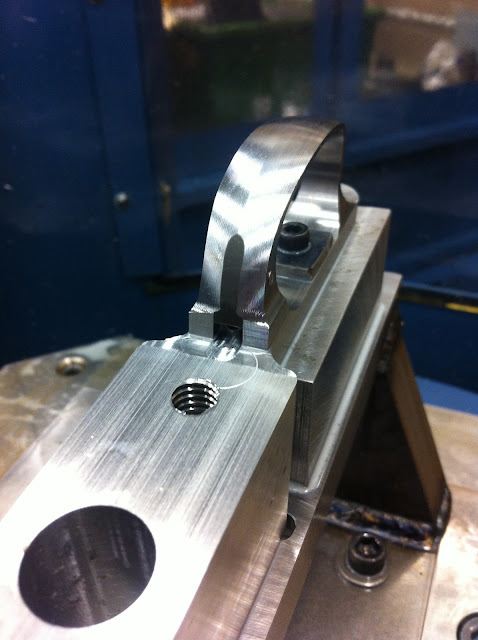

The Planning of this rifle took some time, as did the acquiring all of the appropriate components. D'Arcy had two Magnum magazine assembly blanks left over in inventory from the construction of a pair of 505 Gibbs rifles. The exterior of the assemblies were 70% machined with the exception of the release latch slot and the actual release. Magazine material was made from 4130 chrome-moly steel that had a Rockwell hardness of 30-C to prevent the front and rear wall of the magazine to be damaged during recoil. The no one-size-fits-all approach that Echols is known for would apply here- this magazine would be made specifically for the 45O Rigby cartridge to insure absolute reliability. To that end, the geometry of the inside of the magazine was determined. An EDM wire internally cut the required taper inside the magazine boxes well as the relief pockets along the sidewalls to reduce friction between the cases and the sides of the magazine wall as the rounds rose out of the magazine.

There was one appropriate floor plate left over from the Gibbs projects and it was carefully fit to the magazine assembly, the release lever fit and pinned and then the floor-plate pivot hole drilled and reamed. Then the final shape of the bow was contoured with a series of hand files and many years of acquired skill.

Hugh Henriksen was tasked to making the 450 Rigby reamer and gauges and, soon enough, that tooling arrived. A 1-14 twist was ordered from Krieger but later on LB requested a 1-12 Twist. The presses stopped as Krieger went back to work.

With a mental blueprint and enough parts, it was time to stop agonizing over details and make something. In the next installment, we will follow D’Arcy through the process of turning L.B.’s dream into a reality.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.