There is a point when the mouse, the calipers and in my case even the pencil are set aside and chips need to me made. With most of the initial fixtures now on-line material began to arrive and be cut to length.

With the first machine operation completed the pair is prepped for the next OP. Notice the lower half of the recoil lug located on the northern end of these two billets. Ser # 0001 and #0002 began to take shape.

While these first receivers were being made I spent more than a few hours in the plant watching the magic unfold. When this receiver was pulled off the fixture I must have resembled a Raccoon with a newly found piece of tin foil, It was difficult to let go.

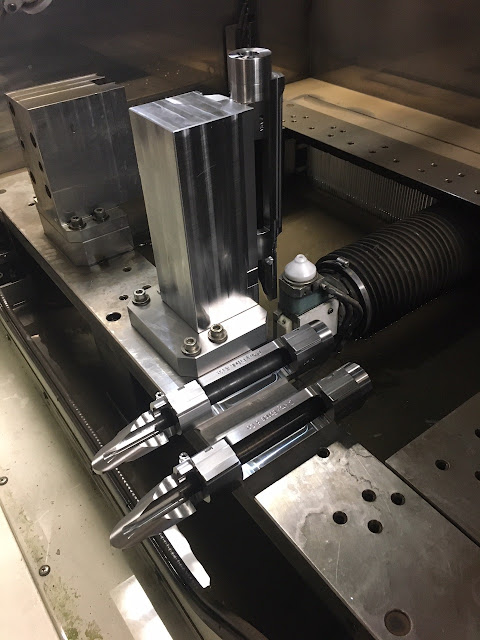

The quality of the CVM machine finish is always excellent

The receiver is one thing, the additional parts then began to add up. With the exception of the Floor-plate, trigger bows, magazine boxes and followers which I have had produced for decades the rest of the newly designed parts began to fall into place.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.